C. Ferekides, T. Copeland-Johnson, A. Dagly, M. Ferraz, P. Ronqui, S. Pokol, E. Purcell

Purpose

Further advancements of II-IV (CdSe, CdTe, and ZnTe) based Thin-Film Photovoltaic (PV) Cells can only be achieved by improving their efficiency and minimizing the amount of scarce raw materials that go into their design. Furthermore, current heat-treatment methods hinder further improvements in the materials conversion efficiency due to unfavorable alterations in their chemical composition. This project aims at understanding the impact of variations in transport properties and doping levels during the synthesis of homojunction and heterojunction II-IV Thin-Film PV Cells, particularly those based on CdTe. Ultimately, the specifications that invoke optimal performance will then be utilized towards the manufacturing of these cells. CdTe is the subject of our investigation because it is the least-expensive PV product in the world today.

Objectives

Our Main objectives for this project include:

1. Constructing an apparatus for forming II-IV Based Thin-Film PV cells via elemental vapor deposition of respective constituents and dopants at atmospheric pressure.

2. Studying the impact of varying the stoichiometric ratios of II-IV components and substrate temperature on the properties of the resulting films and expanding those parameters to formulate a means of maximizing the incorporation of extrinsic dopants.

3. Observing the impact of adding multiple dopants versus a single dopant.

4. Ultimately improving the performance of homojunction and heterojunction PV Cells

Experimental Design

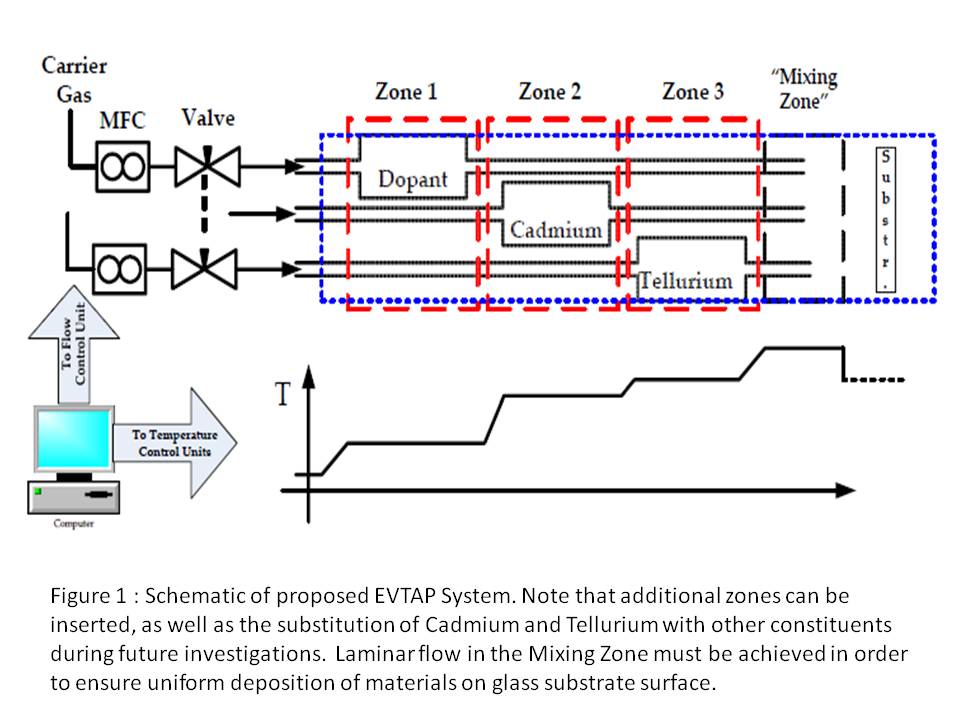

Experimental design consists of the creation of an Elemental Vapor Transport at Atmospheric Pressure (EVTAP) apparatus for controlling the stoichiometric ratios of all the components (Cd, Te, Se, Zn, Se, S, etc.), including dopants (Cu, Cl, O2, etc.). Such methods have proven to lead to improvements in the conversion efficiency of other types of thin-film PV cells, including Copper-Indium-Gallium-Selenide (CIGS) PV cells. The deposition apparatus is cylindrical shaped, comprised of several zones made of graphite, which house the constituent elements and dopants. Each zone is thermally insulated, to minimize stray heat transfer by a ceramic layer. This segment is then encased in a quartz cylinder, with each area corresponding to a zone surrounded by a ring of halogen lamps that heat the each zone independently. A computer controls the temperature in each zone. Threaded through the zones are graphite pipes, which transport a mixture of each vaporized constituent and inert carrier gas, via mass flow controllers (MFC), also operated by a computer, to be deposited on a glass substrate loaded in the mixing zone. From the entrance of the carrier gas to the location of the substrate, the temperature gradient within the apparatus increases towards the maximum temperature of the system.

Characterization analysis techniques are divided into four major categories:

1) Impurity Profiling and Identification: Development of dopant profiles and calculation of their impact on conversion efficiency through Auger Spectroscopy and SIMS Analysis using facilities at the National Renewable Energy Laboratory (NREL).

2) Electrical Properties: Hall Effect, 4-Point Probe Method, and additional instruments, such as impedance analyzers, to measure resistivity, Current-Voltage, and Capacitance-Voltage.

3) Optical Properties: Optical ORIEL Monochrometry to measure Optical Transmissions. Photoluminescence studies conducted at the University of Moldova will determine correlations between gap states between intrinsic and extrinsic defects in the film, based on changes in temperature.

4) Structural and Morphological Properties: X-Ray Diffraction, SEM, and AFM analysis of morphological characteristics of films.

——————————————————-

Bibliography

C. Ferekides and D. Morel, “Developing the Path Toward Realizing the Full Potential of II-VI Based Photovoltaic Materials.” University of South Florida: National Science Foundation, 2010, p. 15.